When do you need to contact an electrician to fix your electrical motor? If you have an older motor, you might be wondering where to get the right service. Before contacting an electrician, check the motor’s warranty and repair history. You can estimate the life of your motor after a repair based on its repair history. Bearing failure is the most common cause of electric motor failure. Poor maintenance practices such as overloading, improper grease, and not cleaning the motor can lead to bearing failures. Continue reading to know when you need electric motor repair services.

Signs of a Failing Electric Motor

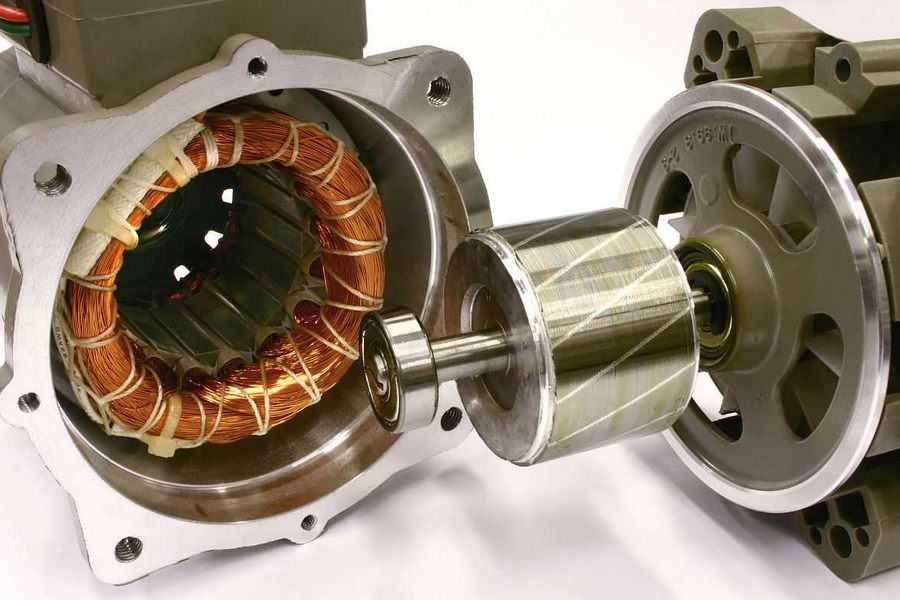

Electric motors are widely used in industrial processes, and if you want to extend their life, you need to be aware of the signs of a failing electric motor. There are some red flags to look out for, such as vibrations or abnormal component temperatures. If you are not able to spot these symptoms, call a repair specialist to assess the condition of the electric motor. Knowing the signs of a failing electric motor will help you make the proper repairs before it leads to an emergency.

Preventive Maintenance

Considering preventive maintenance for your electric motors is essential to their efficiency. While the insulation system is no longer exposed to high temperatures, the most common electric motor error is still noise or damage to the bearings. Proper lubrication is essential to prevent premature bearing failure. In addition, regular inspections can detect signs of a deteriorating bearing. By following these preventive maintenance tips, you can ensure the lifespan of your electric motors and save a lot of money in the long run.

Upgrade Repair

An electric motor plays an important role in a wide variety of operations. While a refurbished motor may save money in the short term, it may not be as reliable as a replacement. Electric motors require regular maintenance to extend their life and efficiency. A qualified electrician can identify the causes of failure and recommend solutions to extend their lifespan. Here are five common reasons for electric motor failure. Inadequate bearing lubrication, excessive vibration, improper grease, and lack of cleaning are common culprits.

Cost of Repair

When a motor breaks down, a facility manager must decide whether to fix it themselves or replace it with a new one. While repairing an electric motor can be cost-effective, it will not guarantee its long-term reliability and efficiency. To make a decision about the cost of electric motor repair, facility managers must first identify which motors they will need to replace. Visit Ghaima Group for more.

Skydiver, maker, audiophile, Vignelli fan and TDC honorary member. Working at the nexus of simplicity and mathematics to craft experiences both online and in real life. I sometimes make random things with friends.